Surface treatment

There are different types of surface treatments, all with different goals. Surface treatments are methods of making products or materials meet certain desired criteria. For example, to counteract wear and corrosion or to obtain a surface with a special aesthetic. One method does not exclude the other and so there are several possible combinations, each combination having unique properties.

Powder coating

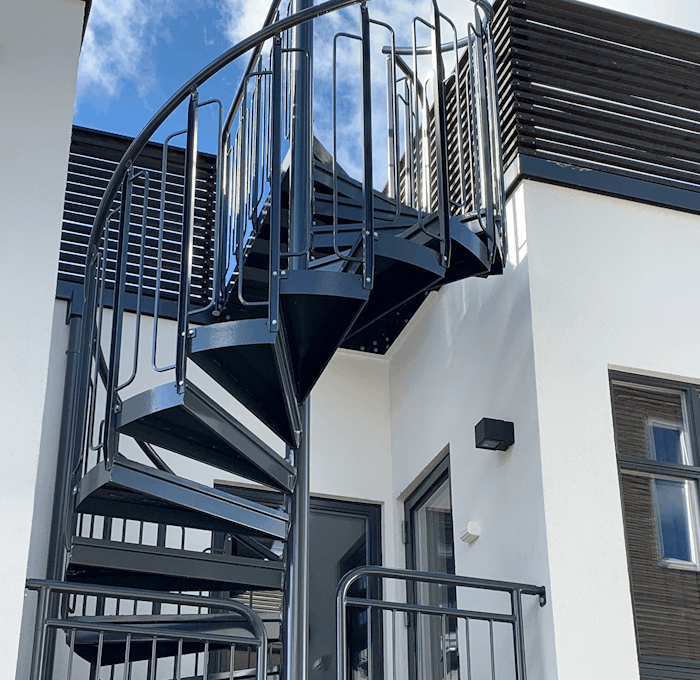

Solely powder coating as surface treatment should only be used for products that are placed indoors. Powder coating is a durable, protective, and environmentally friendly method for surface treatment method. Compared to traditional painting which consists of much solvent the powder coating is much less polluting. The method can be used to paint many types of material. As color surface the powder coating is enduring and handle both mechanical strains and strong chemicals. The application is done in a dry and electronic way which facilitates an even distribution of the color particles and it is easy to access hidden angles. Powder coat the staircase in optional RAL color. We have the most common colors in stock.

Why does Eurostair® use powder coating?

Eurostairs® products should always be of highest quality, have a well-thought out construction and give more value, including to the environment. Powder coating is a very environmentally effective treatment. Color is applicated without any solvent and gives minimal overspray. Today this is the leading method to paint in an environmentally friendly way. It is also the best painting method when it comes to work environment. The people working with powder coating do not have to stand in a cloud of solvent. For us at Eurostair®, powder coating is the obvious choice.

Methods for powder coating

Painting with powder coating offers an unlimited choice of color with a very good color match. Powder coating is the dominating painting method today. Powder coating is done with polyester powder with a layer thickness of approximately 60 my. There are not any limitations when it comes to colors. Today we can paint with the whole RAL-scale but also NCS-S if you prefer. It is important to state the gloss when you chose color. Eurostair® recommend gloss between 80-30 where 80 in blanc and 30 is matt.

Description of the process

To get the right quality of the painted surface it is important with both pretreatment and application of the coat as the following hardening. Since you want to achieve maximal adhesion and sustainability the pretreatment is crucial. The pretreatment normally consists of degreasing and grazing of the surface followed by a chrome free chemical treatment. The pretreatment ends when the material is washed in deionized water. The pretreatment gives the absolute best corrosion resistance and adhesion for products that should be used outdoors. The polyester powder is then applicated by an electrostatic or friction charge and afterwards the powder is hardening in an oven at minimum 180 ºC. Powder coat is applicated and hardened without any solvent. The ventilation air from the powder application is cleaned in effective purifications. The powder that misses the material is taken care of in a recycling system and reversed to the spray gun.

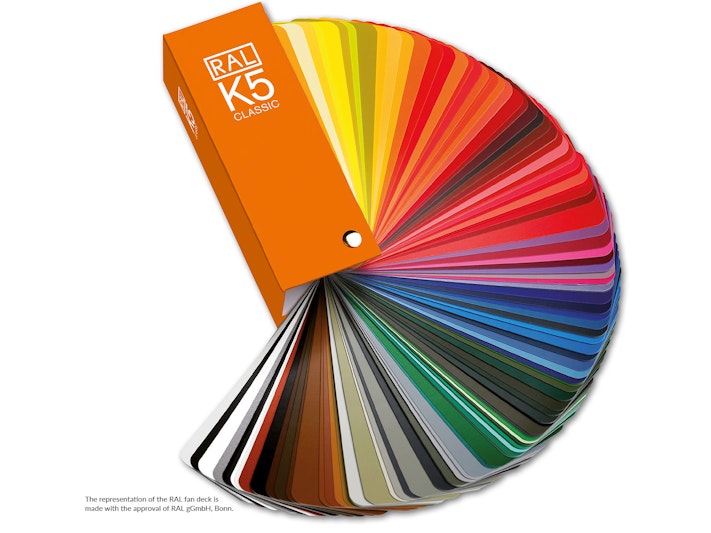

RAL colors

Eurostair® has chosen RAL Classic® to offer colour-stable industrial colours.

From the 215 shades of the RAL scale, 18 colors were selected as the standard color for our products.

Optionally, we can paint your product in any desired color.

WHY DID WE CHOOSE RAL AND NOT NCS?

RAL Classic is a color collection that is mainly based on the requirements of industry. These colors are based on a standardized four-digit color code.

RAL has set a number of criteria for creating an industrial color scale.

- The color must be of overriding public interest and not a matter of fashion.

- The color must have a certain minimum distance to existing ones.

- The commercially available pigments, which are not proven to be environmentally hazardous, must be able to be tinted.

- With a few exceptions, the color must have good opacity on "black and white".

- The color must be able to be produced in such a way that good wear resistance is guaranteed.

- Since our products often have to interact with other details to form a whole, we rely on the RAL color system to ensure high quality.

GLOSS, GLOSS

High gloss 80 ≤ x <90 at 60° angle

Satin 35 ≤ x <60 at 60° angle

What do the different gloss values look like? You can say that shiny is 80 - 95* gloss value.

Satin corresponds to 63 - 77 * gloss value. To obtain an evenly matt color, the gloss level is 20 - 30*.

(* Gloss according to ISO 2813/60° angle)

Our standard colors

Eurostair® offers a quality color system by using the standard RAL Classic®. We have selected 18 colors that are Eurostair® Standard colors to match the industry's standard colors. As an option, we can paint any RAL color you wish, there are 215 different colors to choose from.

RAL 1003

Eurostair® yellow

RAL 9010

Pure white

RAL 9016

Traffic white

RAL 9003

Signal white

RAL 7035

Light grey

RAL 7042

Traffic grey

RAL 7024

Graphite grey

RAL 7016

Anthracite grey

RAL 2003

Pastel orange

RAL 3002

Carmine red

RAL 3009

Oxide red

RAL 8004

Copper brown

RAL 5024

Pastel blue

RAL 5010

Gentian blue

RAL 5000

Violet blue

RAL 9005

Jet black

RAL 6024

Traffic green

RAL 6027

Light green