Options for spiral staircase standard

We use standard components to achieve a rational production which results both in good pricing and continuously high build quality. The stairs are of course customized specifically for your facility and your demands.

The components that a Eurostair® spiral staircase consists of are available in different designs. You can read more about the options for each component under each category below.

Spiral staircases made of high-strength steel, easy and quick to assemble.

From one of the leading staircase manufacturers in Europe.

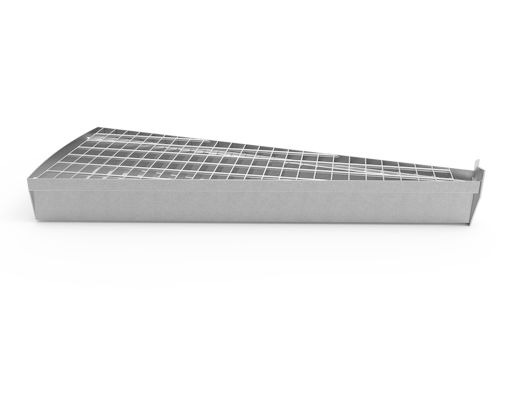

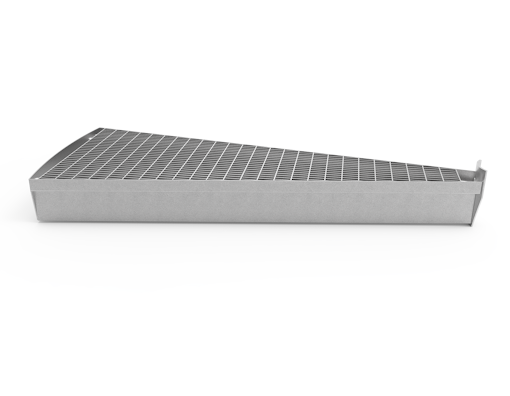

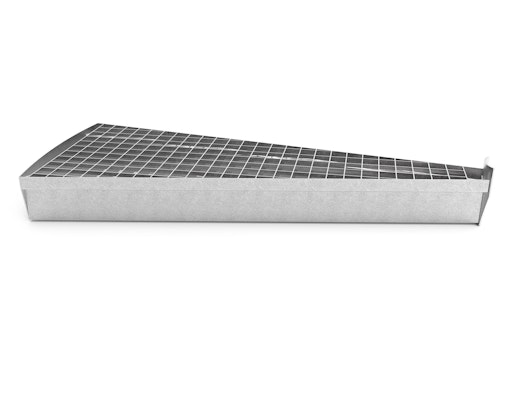

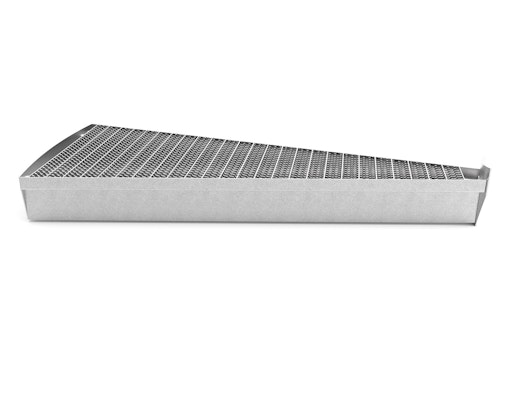

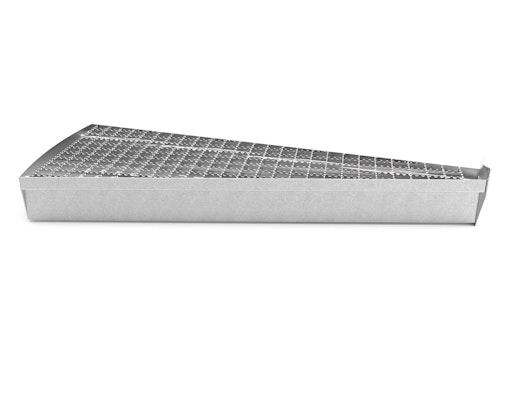

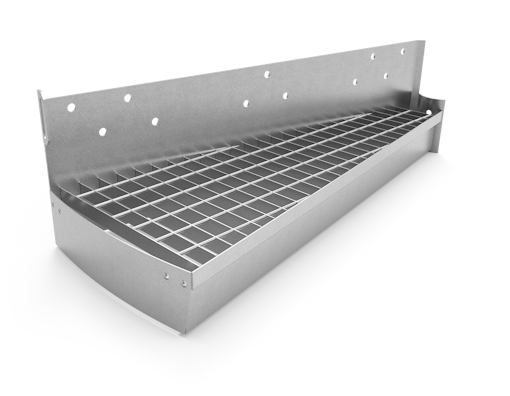

Step surfaces

There are different step surfaces to choose from. Outdoors gratings are often used as the step surface since they work as non-slip surfaces and do not collect snow and rain on the surface. Further, it does not interfere with the overall visual impression of the building since the stair easily blends into the background. For a spiral staircase for inside use, you can choose a wood surface or rug for a softer and quieter stair.

Railings

Our standard range offers five different stair railings. In all five options, the railing post consists of rods with a U-profile. You simply choose the model for your staircase that is best suited to the area. Two of the stair railing options are child-safe models. In order for a spiral staircase to be completely child-safe, no opening must be larger than 100 mm.

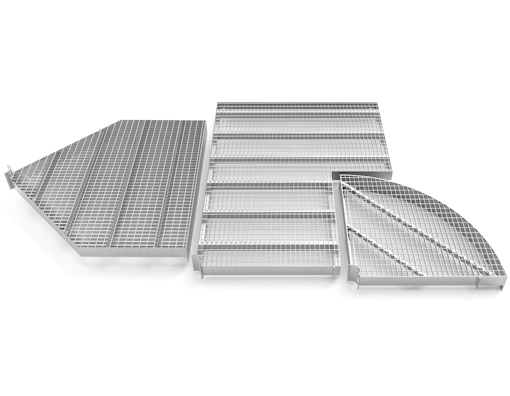

Platforms

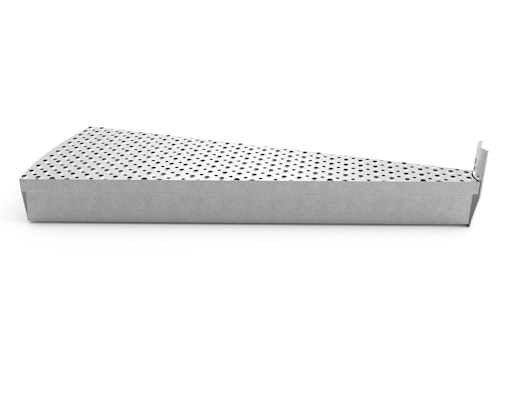

There are two different types of platforms: the exit platform, which ends the staircase going up, and the landing platform (landing) between the different sections of a staircase. Both types typically have a surface of galvanized grating, but can also be made with teardrop, perforated or smooth sheet metal. The railing of a platform, like the other components of the stairs, is available in an industrial or child-safe version.

Large platforms should be mounted on the facade using brackets before the center pipe is installed. However, this is all described in detail in the drawings and assembly instructions that accompany the stairs.

Of course, the staircase is built specifically for your construction project with the necessary platform angles to adjust the exit to the desired position.

Handrails

The handrail of a Eurostair® spiral staircase is manufactured using modern technology, craftsmanship and the necessary know-how. There are no sharp breaks or protruding screws to be found on the Eurostair handrail. The design is carefully thought out to provide the best comfort. The inner handrail is also placed so that you do not get your hands or clothes caught.

Our stair handrails are divided into sections that span 3, 4 or 5 steps and are mounted to the railing posts. To connect the handrails we use a unique and easy to install sleeve at the bottom of the handrail. This provides a stable handrail with discrete connections. Thanks to the paneling, you can follow the handrail with your hand throughout without having to let go in between.

The lower part of the handrail serves as a support to the ground. At the bottom of the handrail there is an adjustable foot that can be anchored in the ground depending on the setting.

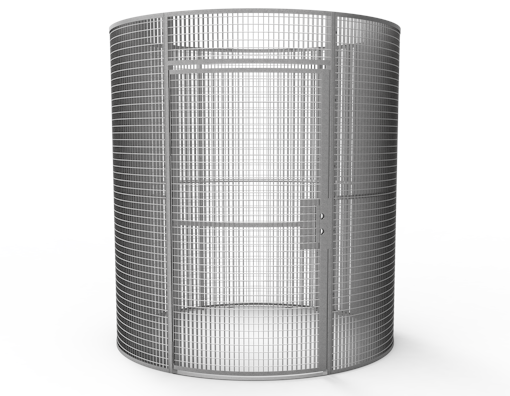

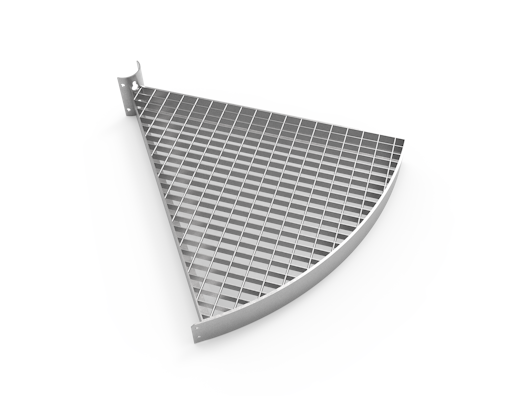

Protective cages

In environments where children are regularly present or there is a risk of unwanted access, you can add a protective cage to your staircase to prevent access to the spiral staircase. Depending on your wishes, protective cages can look different and have different heights. As standard, we produce the cage as a rounded quarter cage made of grating, but cages anchored to the ground are also common. These are then placed outside the stair construction.